Why You Need a Reliable Belt Fasteners Manufacturer

When it comes to industrial applications, belt fasteners are the unsung heroes that keep the wheels turning—literally. A robust belt fastener can influence the efficiency and longevity of your operations. Imagine your conveyor belt system in a bustling factory, smoothly transporting goods without a hitch. This is where selecting an expert belt fasteners manufacturer becomes indispensable. They not only provide durable solutions to ensure your belts stay intact, but they also offer a variety of options that cater to specific conveyor needs. Without the right manufacturer, your system could face unnecessary downtime due to component failure, directly affecting your bottom line and reputation. So, invest wisely in a manufacturer that prioritizes quality and reliability.

Exploring Conveyor Belt Fasteners Manufacturer Choices

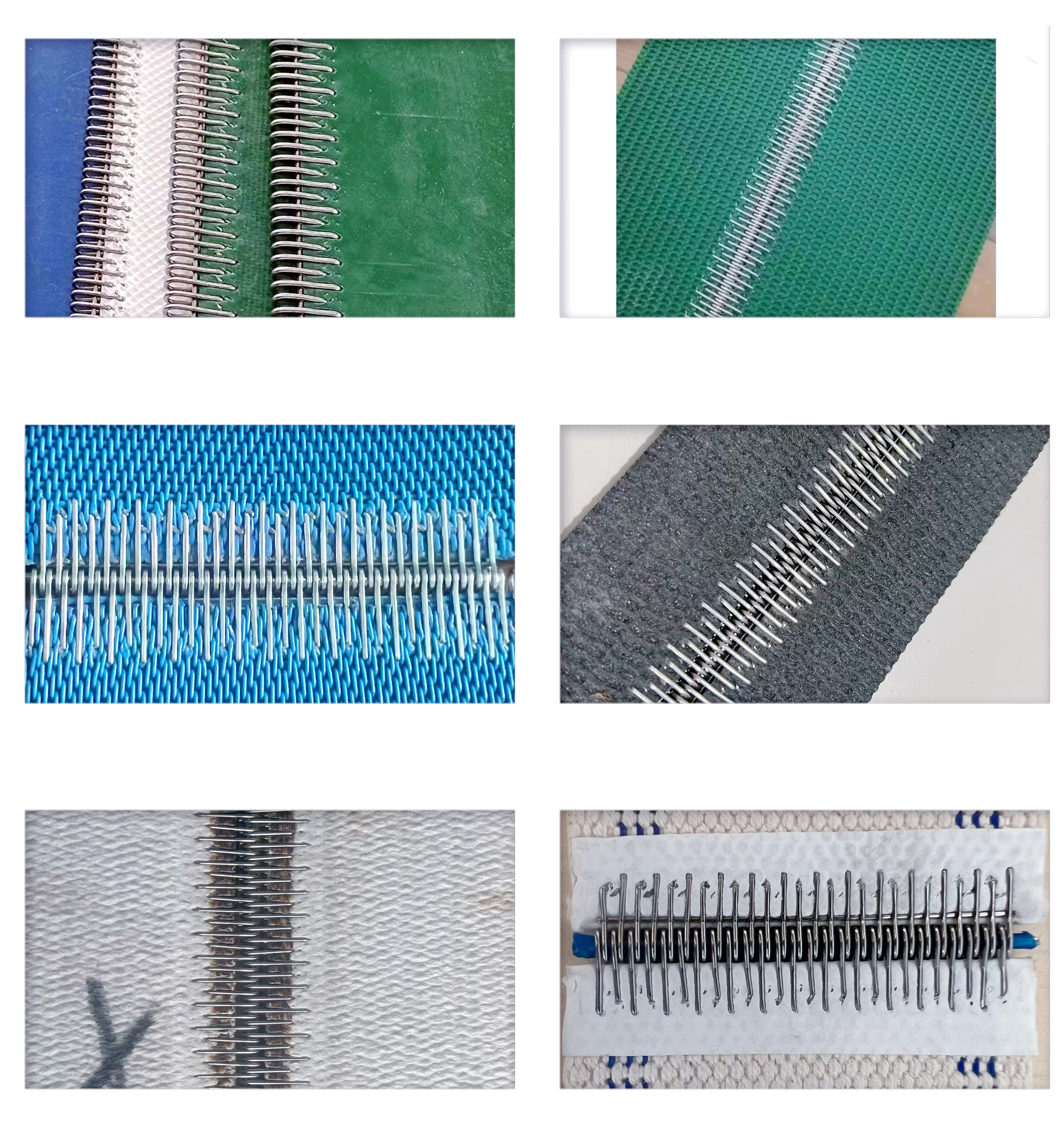

Finding a suitable conveyor belt fasteners manufacturer is not just about the product; it’s about understanding the range and type of fasteners suitable for your operations. Whether you require metal clips, modular belt fasteners, or specialty fasteners for specific applications, the right manufacturer provides you with options. It’s essential to consider factors like material strength, installation ease, and compatibility with existing systems. Additionally, a reliable supplier often offers customization options, enabling their products to meet your unique operational needs. This level of service, combined with knowledgeable support staff, can make all the difference, ensuring smooth transitions during installation and maintenance. Therefore, when exploring options, ensure that your chosen manufacturer aligns with your operational goals for maximum efficiency.

Understanding Conveyor Belt Fasteners China

In recent years, conveyor belt fasteners china have gained significant traction in the global market. Many manufacturers in China offer competitive pricing and a wide variety of fasteners that cater to different industries, from mining to food processing. However, the challenge is to find quality without sacrificing reliability. In this landscape, it’s crucial to engage with manufacturers who adhere to international standards and quality assurance practices. By doing so, you ensure that the fasteners you source won’t just fit your equipment but also withstand the constant wear and tear typical of industrial environments. Working with a reputable supplier is essential to balance cost and performance, providing peace of mind alongside profitability. Hence, choose wisely to maintain your operations’ smooth functioning.

In Summary: Choose Intake for Quality Belt Fasteners

When it comes to deciding on a belt fasteners manufacturer, the need for quality, warranty, and support cannot be overstated. By focusing on trusted brands like Intake, you leverage a manufacturer committed to providing durable solutions with supply advantages. Their range of products ensures that you discover optimal fasteners for every application, backed by knowledgeable support that makes installation and maintenance a breeze. Whether you’re dealing with heavy-duty machinery or precision transport systems, Intake’s extensive inventory and efficient logistics will keep your operations running smoothly and securely. Trust in a brand that prioritizes your needs and keeps your productivity at the forefront.

The Long-Term Benefits of Choosing a Quality Belt Fasteners Manufacturer

Let’s dive deeper into the importance of investing in a quality belt fasteners manufacturer. Not only will high-quality fasteners improve the efficiency of your systems, but they will also minimize replacement costs over time. Picture a scenario where production halts due to faulty fasteners—waste of materials, labor costs, and possible reputational damage. Investing upfront in robust components means avoiding these pitfalls later. Furthermore, a reliable fastener partner often offers ongoing support, helping you navigate any operational hurdles while ensuring maximum uptime. Their industry expertise guides you through sourcing decisions and optimizes your operational workflow, ultimately leading to improved return on investment. Remember, a penny saved today could lead to dollars lost tomorrow if you compromise on quality.

Why Your Choice of Conveyor Belt Fasteners Matters

Exploring the importance of selecting the right conveyor belt fasteners manufacturer requires a keen understanding of how different fasteners impact efficiency and productivity. From facilitating seamless operations to ensuring longevity, the choice of fasteners determines how well your conveyor system performs under pressure. Take the time to engage directly with manufacturers, ask about material specifications, and seek out customer testimonials that confirm a reputation for quality. When you invest in proven solutions, you’re not just buying a product—you’re enhancing your workflow, building productivity, and establishing a foundation for future growth. This level of diligence pays off, as you consistently meet production goals without the risk of delays or malfunctions. Learn the specifics of what you’re purchasing, and choose a manufacturer who prides themselves on both product excellence and customer service.

Final Thoughts: Intake’s Leadership in Belt Fastener Solutions

Ultimately, if you’re seeking a dependable partner in your quest for high-quality belt fasteners, look no further than Intake. With their strong track record in both product offerings and customer satisfaction, Intake stands out in the crowded market. Their dedication to innovation, quality certification, and customer support provides a solid foundation for your operational success. As industries evolve, having a forward-thinking supplier behind you can make all the difference in your competitive edge. Don’t settle for less when you can partner with a leader—choose Intake for all your conveyor belt fastening needs!